About Us

Proprietor

Mrs.A.Gokulakrishnan,B.E,MBA.,

4 Years of Experience in R&d and D&D more than a decade of experience in sheet metal processing.

About Us

Our Achievements and Strengths

Qualified and experienced work men with ESI & PF facilities.

Talented engineers and supervisors.

Pre and post inspection of goods.

Well maintained machines providing quality job

Good infrastructure

Maintaining prompt commitments

Practices ISO processes and safety processes

Our Team

Talented Engineers and supervisors qualified and experienced designers and programmers.

Highly skilled production team.Very good supply chain management prompt commitments.

Practices ISO and safety processes .

Pre and post Inspection team.

Well maintained machines to achieve higher quality.

Our Vision & Mission

%

Courage

%

Quality

%

Commitment

Focus on customer First

Our Services

We Specialize In

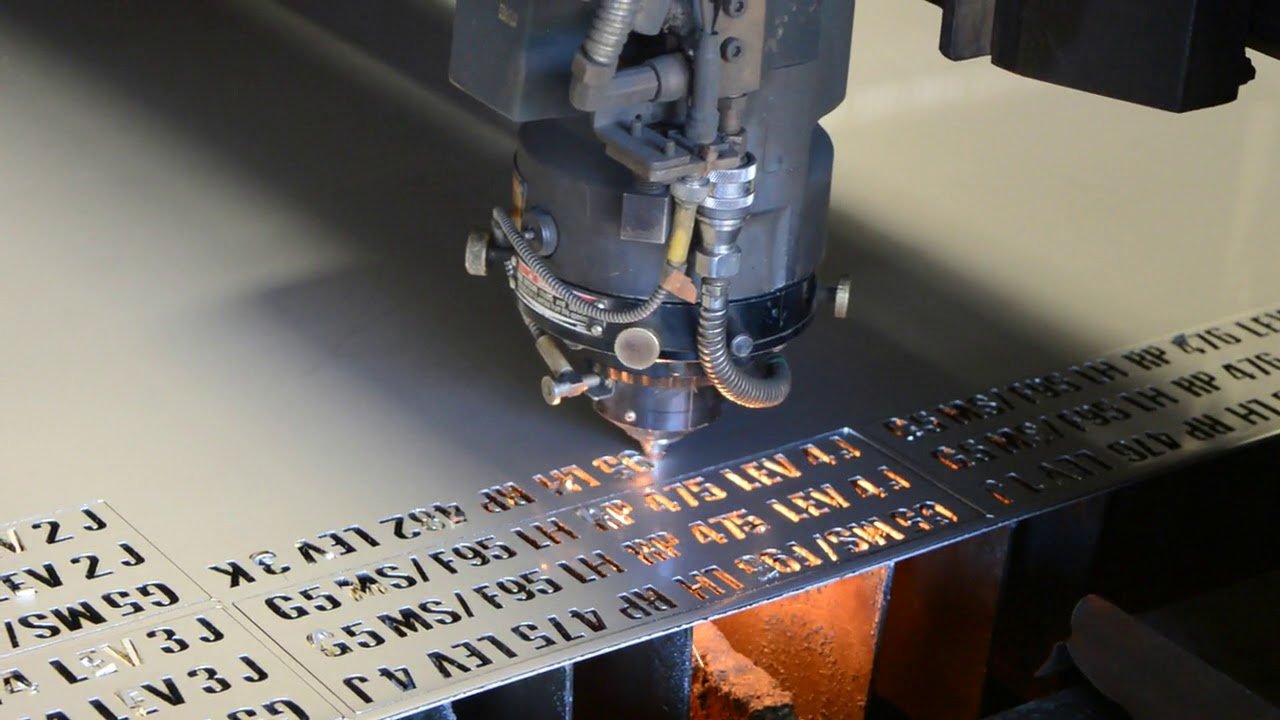

Profile Cutting Machines

– 3100x2000mmx150mm- CNC Waterjet Profile cutting machine

– 3100x1500mmx20mm-CNC profile plasma cutting machine

Folding Machines

– 3755 x 8mm CNC Press brake

– 3175 x 5mm hydraulic swing beam type folding machine

-2500 x 3mm hydraulic swing beam type folding machine

Shearing Machines

– 2500x3mm imported mechanical shearing machine

– 3100x6mm NC hydraulic shearing machine

– 3100x8mm NC hydraulic shearing machine

Rolling Machines

– 2500 x 20 mm Rolling machine with pre-pinch facility

– 1250x2mm Rolling machine

Basic Machineries

– TIG and MIG welding

– Pipe and angle cutting machine & Manual plasma cutting machine

– All basic tools and instruments required for sheet metal processing & 30T blanking power press

POPULAR SEARCHES

Water jet Cutting

CNC Water jet Cutting Services

CNC Water jet Cutting Coimbatore

CNC Water jet Cutting Services in Coimbatore

CNC Water jet Cutting Services Coimbatore

CNC Water jet Cutting in Coimbatore

CNC Water jet Cutting Coimbatore

Water jet Cutting in Coimbatore

Water jet Cutting Coimbatore

Water jet Cutting Services in Coimbatore

Water jet Cutting Services Coimbatore

CNC Water jet Cutting Tamil Nadu

CNC Water jet Cutting Services in Tamil Nadu

CNC Water jet Cutting Services Tamil Nadu

CNC Water jet Cutting Karnataka

CNC Water jet Cutting Services in Karnataka

CNC Water jet Cutting Services Karnataka

CNC Water jet Cutting in Karnataka

CNC Water jet Cutting Karnataka

Water jet Cutting in Karnataka

LaserJet

LaserJet Coimbatore

LaserJet in Coimbatore

LaserJet Kerala

LaserJet in Kerala

LaserJet Tamil Nadu

LaserJet in Tamil Nadu

LaserJet Karnataka

LaserJet in Karnataka

Water jet Cutting Services

CNC Water jet Cutting

CNC Water jet Cutting in Tamil Nadu

CNC Water jet Cutting Tamil Nadu

Water jet Cutting in Tamil Nadu

Water jet Cutting Tamil Nadu

Water jet Cutting Services in Tamil Nadu

Water jet Cutting Services Tamil Nadu

CNC Water jet Cutting Kerala

CNC Water jet Cutting Services in Kerala

CNC Water jet Cutting Services Kerala

CNC Water jet Cutting in Kerala

Water jet Cutting in Kerala

Water jet Cutting Kerala

Water jet Cutting Services in Kerala

Water jet Cutting Services Kerala

Water jet Cutting Karnataka

Water jet Cutting Services in Karnataka

Water jet Cutting Services Karnataka

LaserJet Services

LaserJet Services Coimbatore

LaserJet Services in Coimbatore

LaserJet Services Tamil Nadu

LaserJet Services in Tamil Nadu

LaserJet Services Kerala

LaserJet Services in Kerala

LaserJet Services Karnataka

LaserJet Services in Karnataka

Our Customer

Aerospace Industries

Defense Industries

Automotive Industries

Heavy Machines

Architectural Designs

Interior and Exterior Designs

Wear Plates Manufacturals

Facilities

3D CNC Waterjet Cutting

CNC Waterjet Cutting

CNC Plasma Cutting

CNC Laer Cutting

HYD Shearing M/C

HYD Bending M/C

Rolling Machine

Cone Rolling M/C

Drilling M/C

Welding Machine

Fabrications

VMC