3D Waterjet Cutting

3D Waterjet Cutting,

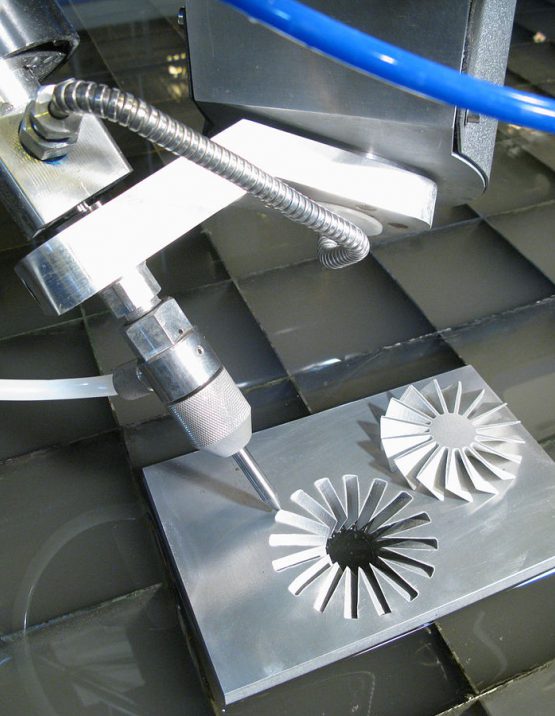

With recent advances in control and motion technology, 3D Waterjet Cutting in Coimbatore

(abrasive and pure water) has become a reality. Where the normal axis on a water jet are named X (back/forth), Y (left/right), and Z (up/down). 3D cutting opens up a wide range of applications that can be done on the Waterjet Coimbatore. As it is still a relatively new technology, from a business standpoint, the profit margins from this type of work can be very attractive.

Why 3D waterjet is Used?

3D Waterjet Cutting,

Provides for up to 60 and also 90 degrees of motion giving you the ultimate in accuracy, speed, and flexibility and get high accuracy cutting.

Advantage of 3D Watrejet Cutting

Excellent cut quality

High processing speed

High accuracy

3D Waterjet in Kerala,

the cold cutting technique prevents the change of structure to the base material. Water jet Services In Tamil Nadu, this means that the material will not discolor, deform, or change during the process.

Waterjet Cutting Services in Karnataka

is suitable for a wide range of materials. No deformation, discoloration, and change of base material structure and basic material is used optimally, no rework.

CNC Water jet cutting services,

Cut complex shapes with a single operation, including welding edges.

GREAT FEATURES of 3D WATERJET CUTTING

Better Surface Finish

Longer Tool Life

Allows tool to reach difficult places smoothly

Reduced setup time

Increased accuracy

Expanded shop capability for future work

POPULAR SEARCHES

Waterjet Coimbatore

Waterjet in Coimbatore

Waterjet Cutting Coimbatore

Waterjet Cutting Services in Coimbatore

CNC Water jet cutting services Coimbatore

CNC Water jet cutting Coimbatore

Waterjet Tamil Nadu

Waterjet in Tamil Nadu

Waterjet Cutting Tamil Nadu

Waterjet Cutting Services in Tamil Nadu

CNC Water jet cutting services Tamil Nadu

CNC Water jet cutting Tamil Nadu

Waterjet Kerala

Waterjet in Kerala

Waterjet Cutting Kerala

Waterjet Cutting Services in Kerala

CNC Water jet cutting services Kerala

CNC Water jet cutting Kerala

Waterjet Karnataka

Waterjet in Karnataka

Waterjet Cutting Karnataka

Waterjet Cutting Services in Karnataka

CNC Water jet cutting services Karnataka