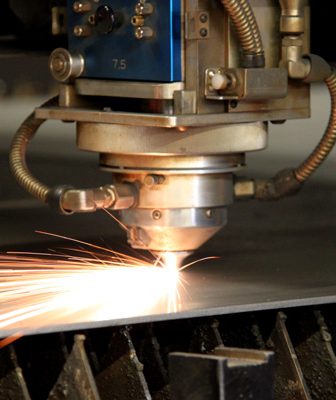

CNC Laser Cutting Machine

Laser Cutting Machine

MITSUBISHI Laser Cutting Machine – 3KW

Specification:

Pallet Size: 3000 X 1500 mm

Maximum Thickness:

MS: Up to – 16mm

SS: UP to – 12mm

List of Machineries

| S.No | MACHINE | PROCESS | SIZE | CAPACITY | MATERIAL |

|---|---|---|---|---|---|

| 1 | 3D-5-Axis Water Jet | Profile Cutting | 3000 x 2000mm | 0.5mm to 300mm ( upto 60 degree of head rotation) | Any Material (Metal & Non-Metals) |

| CNC Water Jet 5 Axis waterjet | Profile Cutting | 4000 x 2000mm | 0.5mm to 300m | Any Material (Metal & Non-Metals) | |

| CNC Water Jet 3 axis | Profile Cutting | 4000 x 2000mm (upto 6mtr can be processed) | 0.5mm to 150mm | Any Material (Metal & Non-Metals) | |

| CNC Water Jet 3 axis | Profile Cutting | 3000 x 2000mm (upto 6mtr can be processed) | 0.5mm to 150mm | Any Material (Metal & Non-Metals) | |

| 2 | CNC Laser Cutting | Profile Cutting | 3100 x 1500mm | 0.5mm to 20mm | MS, SS & Aluminum |

| 3 | CNC Punching Machine | Punching & Perforation | 2500 x 1500mm | 0.5mm to 4mm |

All Metals |

| 4 | CNC Plasma Cutting | Profile Cutting | 4000 x 2000mm | Up to 50mm MS | SS & Aluminum |

| 5 | CNC Flame (oxy)cutting | Profile & Straight Cutting | Any Size | Up to 250mm | MS |

| 6 | CNC Bending Machine | Folding & Forming | 4meter (13.2 feet) | 20mm plate Bending |

All Metals |

| 7 | Shearing Machine | Cutting | 4100mm | Up to 10mm |

All Metals |

| 8 | Hydraulic Press | Corrugations & Edge Forming | 100 tons | Up to 6mm |

All Metals |

| 9 | Blanking Press | Press Components | 40 tons | Up to 3mm |

All Metals |

| 10 | Rolling Machine | Roll Bending | 250mm | Up to 12mm |

All Metals |

| 11 | Cone Rolling | Cone Rolling | 2500mm | Up to 6mm |

All Metals |

| 12 | Rolling Machine | Special Items | Minimum Dia 100mm |

All Metals | |

| 13 | VMC | MACHINING | 1050 X 1050 |

All Metals | |

| 14 | CNC TURNING | MACHINING | 750 MM DIA – length 3600 mm |

All Metals | |

| 15 | Fabrication Shop | All type of Mig, ARC, Tig welding set-up with crane facility 5 tons |

All Metals | ||

CNC Laser Cutting

CNC Laser Cutting Services, the machine

is an alternate Computer Numerical Controlled procedure that uses laser innovation to cut materials. Laser Cutting is utilized as a part of creation lines and is not intended for household purposes. They must be utilized as a part of a controlled situation by an expert prepared single person. A PC coordinates a high fueled laser on to the fancied material, letting it know where and when to cut, this gives accuracy comes about that would essentially not be conceivable by hand and razor-sharp edge. At the point when the laser comes into contact with the material it either vaporizes, melts, or consumes with extreme heat the remove territory, a few machines utilize a plane of gas to clear out abundance material. The finished result is a great completed edge that is straight and great. Laser slicing apparatus is utilized to cut channeling and structural materials and also level sheet materials.

Laser Cutting Services,

If you are in search of a flexible and cost-effective laser cutting service, go no further! We are a certified company and provide our valued customers with quality CNC Laser Cutting Services in Coimbatore.

As an eminent and renowned company offering laser cutting in Coimbatore for our clients, we offer our services with the help of the latest CNC laser cutting and metal laser cutting equipment.

What is CNC Laser Cutting?

CNC Laser Cutting, CNC stands for ‘Computer Numerical Control’. That means the computer has the ability to change the design patterns into numbers, produced by Computer-Aided Design Software (CAD). These converted numbers control the movement of the cutter. In this way, the computer controls the cutting and engraving of the objects. A CNC Laser Cutter allows for extremely precise cutting and engraving of many materials such as wood, foam, concrete, different metals, and many others. It contains a sharp and pointed router to produce clean and exact cutting of the material. This sharp cutter can even cut most organic materials and depending on the power metals as well.

Advantages of CNC Laser Cutting

- Easy and fast control of the laser power over a wide range (1100%) enables a power reduction on tight or narrow curves.

- Excellent cut quality.

- High processing speed.

- Very small heat-affected zone compared to other thermal cutting processes.

- Very low application of heat, therefore minimum shrinkage of the cut material.

- High accuracy.

- High-pressure laser cutting with nitrogen enables oxide-free cutting.

Why CNC Laser Cutting are used

CNC Lasers are used for many purposes. One way they are used is for cutting metal plates. On mild steel, stainless steel, and aluminum plate, the

CNC Laser

the cutting process is highly accurate, yields excellent cut quality has a very small kerf width and small heat-affected zone, and makes it possible to cut very intricate shapes and small holes.

Methods of Laser Cutting

I. Depending on the material to be cut the cutting methods used differ :

1.Fusion Cutting (high-pressure cutting):

2.The material is fused by the energy of the laser beam.

3.The gas, in this case, nitrogen at high pressure (10 to 20 bar), is used to drive out the molten material from the kerf.

II. Oxidation cutting (laser torch cutting):

1.The material is heated by the laser beam to combustion temperature. The gas also protects the focusing optics from splashes.

POPULAR SEARCHES

CNC Laser Coimbatore

CNC Laser in Coimbatore

CNC Laser Cutting Coimbatore

Laser cutting services Coimbatore

CNC Laser Cutting Services in Coimbatore

Laser cutting in Coimbatore

CNC Laser Tamil Nadu

CNC Laser in Tamil Nadu

CNC Laser Cutting Tamil Nadu

CNC Laser Cutting Services in Tamil Nadu

Laser cutting services Tamil Nadu

Laser cutting Tamil Nadu

CNC Laser Kerala

CNC Laser in Kerala

CNC Laser Cutting Kerala

CNC Laser Cutting Services in Kerala

Laser cutting services Kerala

Laser cutting Kerala

CNC Laser Karnataka

CNC Laser in Karnataka

CNC Laser Cutting Karnataka

CNC Laser Cutting Services in Karnataka

Laser cutting services Karnataka