Why CNC Waterjet Cutting

CNC Waterjet Cutting Machine

5 AXIS -1 No 3 AXIS – 2 No

Specification:

Table Size: 4000 x 2000 x 300mm

Any Material Thickness:

Up to – 300mm

List of Machineries

| S.No | MACHINE | PROCESS | SIZE | CAPACITY | MATERIAL |

| 1 | 3D-5-Axis Water Jet | Profile Cutting | 3000 x 2000mm | 0.5mm to 300mm ( upto 60 degree of head rotation) | Any Material (Metal & Non-Metals) |

| CNC Water Jet 5 Axis waterjet | Profile Cutting | 4000 x 2000mm | 0.5mm to 300m | Any Material (Metal & Non-Metals) | |

| CNC Water Jet 3 axis | Profile Cutting | 4000 x 2000mm (upto 6mtr can be processed) | 0.5mm to 150mm | Any Material (Metal & Non-Metals) | |

| CNC Water Jet 3 axis | Profile Cutting | 3000 x 2000mm (upto 6mtr can be processed) | 0.5mm to 150mm | Any Material (Metal & Non-Metals) | |

| 2 | CNC Laser Cutting | Profile Cutting | 3100 x 1500mm | 0.5mm to 20mm | MS, SS & Aluminum |

| 3 | CNC Punching Machine | Punching & Perforation | 2500 x 1500mm | 0.5mm to 4mm | All Metals |

| 4 | CNC Plasma Cutting | Profile Cutting | 4000 x 2000mm | Up to 50mm MS | SS & Aluminum |

| 5 | CNC Flame (oxy)cutting | Profile & Straight Cutting | Any Size | Up to 250mm | MS |

| 6 | CNC Bending Machine | Folding & Forming | 4meter (13.2 feet) | 20mm plate Bending | All Metals |

| 7 | Shearing Machine | Cutting | 4100mm | Up to 10mm | All Metals |

| 8 | Hydraulic Press | Corrugations & Edge Forming | 100 tons | Up to 6mm | All Metals |

| 9 | Blanking Press | Press Components | 40 tons | Up to 3mm | All Metals |

| 10 | Rolling Machine | Roll Bending | 250mm | Up to 12mm | All Metals |

| 11 | Cone Rolling | Cone Rolling | 2500mm | Up to 6mm | All Metals |

| 12 | Rolling Machine | Special Items | Minimum Dia 100mm | All Metals | |

| 13 | VMC | MACHINING | 1050 X 1050 | All Metals | |

| 14 | CNC TURNING | MACHINING | 750 MM DIA – length 3600 mm | All Metals | |

| 15 | Fabrication Shop | All type of Mig, ARC, Tig welding set-up with crane facility 5 tons | All Metals | ||

CNC Waterjet Cutting Services

CNC Waterjet

cutting blends abrasives alongside water that is constrained from a spout. The weight and quality have the ability to cut stones, marbles, plastic, rock, wood, and different metals. As the methodology does not utilize any unsafe chemicals to perform the errand, it is known as a cool procedure. It doesn’t radiate any unsafe gasses and is environmentally agreeable. With finely finished items, there is no need of completing. That is as of now dealt with while performing the methodology. The edges are fine and smooth with no further work required.

- Cuts through all types of materials

- Environment Friendly

- No heat generation (cold cutting process)

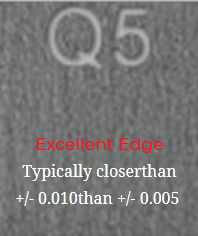

- Accurate and precise cutting, tolerance to ±0.005 inch

- No chemicals, clean cutting, green manufacturing

- No smog, dirt or grime

- No carbon buildup (Green Technology)

- No heat, warping, or discoloration

What is Waterjet Cutting

CNC Waterjet Cutting Services

As the name proposes, waterjet cutting uses the force of water with innovation to get fancied results to shape, cut, and outline diverse metals and materials. With the assistance of this methodology, unpredictable outlines and complex configurations could be possible quiet. Right from the beginning, the method has made a buzz and is running solid and famous with clients. CNC Waterjet the deciding result is fulfilling with outright no mischief to the surface and group of the thing. The method can be an electronic numerical controlled to acquire indistinguishable results. This improves the general aftereffect of the waterjet cutting furthermore does not leave any extent of outlining or cutting lapses. For a flawless cutting procedure, waterjet cutting is the right alternative. Get the most perplexing organizing or outlining done in minutes with this procedure and at savvy rates.

Features of Waterjet cutting

- Cuts through all types of materials

- Environment Friendly

- No heat generation (cold cutting process)

- Accurate and precise cutting

- tolerance to ±0.005 inch

- No chemicals, clean cutting, green manufacturing

- No smog, dirt or grime

- No heat, warping, or discoloration

- No carbon buildup (Green Technology)

What Type of Material Could

Waterjet Cuts?

1. MS

2. SS

3. AL

4. CU

5. Brass

6. Grass

7. Rubber

8. Plastic

9. Composite

10. Nylon

11. Hylem

12. Foam

13. Granite

14. Marble, Tiles, Ceramic.

What Type of Material Could Waterjet Cuts?

- Metal Industry

- Aerospace Industry

- Automotive Industry

- Manufactures of Gasket

- Textile Industry

- Power Generation Industry

- Plastic Paper & Packaging Material Industries

- Road Highway Barriers

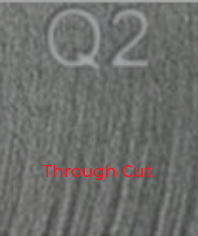

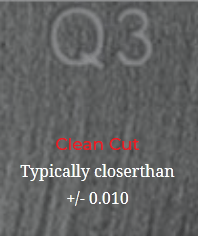

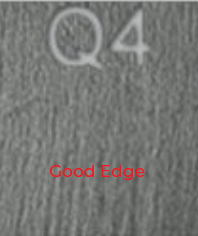

Types of Cutting Finish

PARAMETER |

METAL |

NON METAL |

EDGE BURNING |

BURN ON EDGE |

EDGE FINISH |

EDGE TAP ON HIGHER THICKNESS |

THICKNESS mm(ss/TITANIUM) |

HARDNESS MATERIAL |

COMPOSITES |

BLIND CUTTING |

THERMAL EFFECT |

LASER |

YES |

NO |

YES |

SOME WHAT |

GOOD |

GOOD |

1-10 |

NO |

NO |

SOME WHAT |

NO |

WATERJET |

YES |

YES |

NO |

NO |

BETTER |

BETTER |

0.5 – 150 |

YES |

YES |

BETTER |

NO |

WIRECUT |

YES |

NO |

NO |

NO |

BEST |

BEST |

UPTO 150 |

YES |

ONLY METALIC |

NO |

NO |

POPULAR SEARCHES

CNC Waterjet Coimbatore

Waterjet in Coimbatore

CNC Waterjet Cutting Coimbatore

Waterjet Cutting Services in Coimbatore

Water jet cutting services Coimbatore

Water jet cutting Coimbatore

CNC Waterjet Tamil Nadu

Waterjet in Tamil Nadu

CNC Waterjet Cutting Tamil Nadu

Waterjet Cutting Services in Tamil Nadu

Water jet cutting services Tamil Nadu

Water jet cutting Tamil Nadu

Waterjet Kerala

Waterjet in Kerala

CNC Waterjet Cutting Kerala

Waterjet Cutting Services in Kerala

Water jet cutting services Kerala

Water jet cutting Kerala

CNC Waterjet Karnataka

Waterjet in Karnataka

CNC Waterjet Cutting Karnataka

Waterjet Cutting Services in Karnataka

Water jet cutting services Karnataka