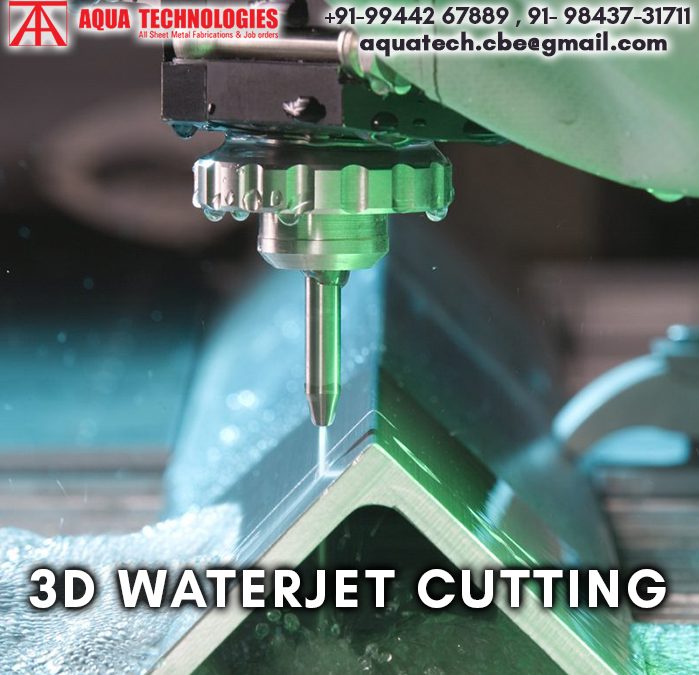

3D Waterjet Cutting

Services is suitable for a wide range of materials. No deformation, discoloration, and change of base material structure and basic material is used optimally, no rework.

CNC Water jet cutting

services, Cut complex shapes with a single operation, including welding edges.

Water jet cutting

is another subtractive manufacturing technique but it uses pressurized water-focused in a very small point to cut the material. The pressure can be as high as 60000 pounds per square inch (4137 bar). The water can be mixed with an abrasive such as garnet, which increases its cutting possibilities (more materials, closer tolerances).

High-pressure water jet cutting machine is widely used in cutting composite materials, rubber, granite, marble, leather, nylon, glass, cloth, tile, food, wood, metal, low melting point, inflammable and explosive materials, such as paper, ammunition, etc. Waterjet cutting advantage: Water cutter belongs to cold cutting equipment, environmental protection, and no thermal impact, smooth cutting edge.

At Aqua Waterjet Cutting, we offer you the best 3D Waterjet Cutting and great Applications such as metal plate designing. Feel free to contact one of our specialists for expert advice.